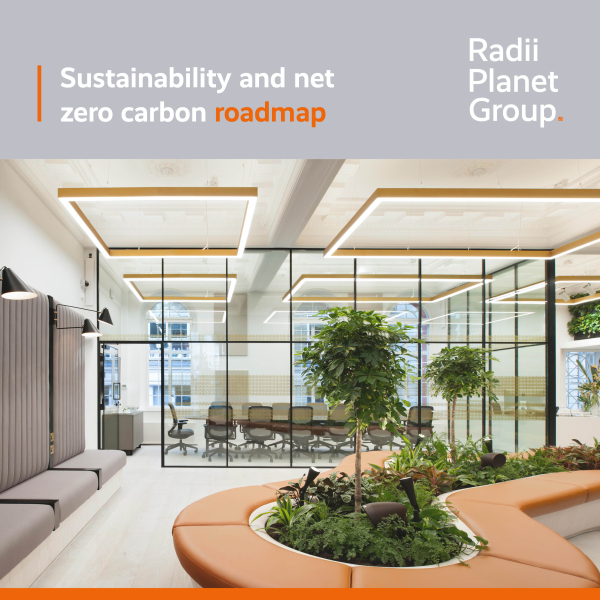

At Radii Planet Group, we recognise that we have a legal and moral responsibility to manage our business operations and reduce any detrimental impact on climate change. We are committed to sustainability and environmental stewardship, integrating these principles into every facet of our organisation.

Our mission at Radii Planet Group is to lead by example in the pursuit of a sustainable future. By embedding these values into our core operations and decision-making processes, we aim to inspire others in our industry and beyond to join us in making a positive difference. Together, we can create a more sustainable world for future generations.

We understand that an organisation such as ours has the opportunity to make a significant difference. This means taking proactive steps to minimise our environmental footprint and promoting practices that contribute to a healthier planet.

For our employees, this involves fostering a culture of sustainability, providing education and resources to encourage eco-friendly practices both in the workplace and at home. We believe that empowering our staff with the knowledge and tools to make sustainable choices is essential for creating a collective impact.

For our stakeholders, we are dedicated to transparency and accountability, regularly reporting on our environmental initiatives and progress. We strive to build strong partnerships with suppliers and clients who share our commitment to sustainability, ensuring that our entire supply chain operates with the highest environmental standards. This collaborative approach helps to amplify our efforts and create a broader positive outcome.

About Us

Products & Services

Sustainability

Our Work

Fit Out Projects

Sectors

Contact Us